Racing a MK5 Rabbit, Drive Belt issues

I started building this MK5 Rabbit for road racing in 2016. I’ve learned a few things over the years that I’ve been running it on track so far. The five cylinder engine, 07K, presents a challenge or two, we have some considerations to take when dealing with ABS and TC, and then there is the question of gearing and tire selection. I will be addressing some of these issues in the next few blog posts, hopefully some of my experience with the car will help get others on track avoiding some of the problems I had.

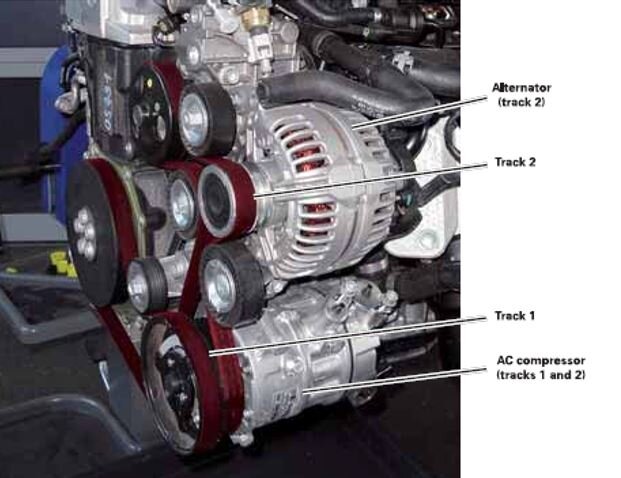

The first issue is the belt drive system on the 07K 5cyl engine. You can find plenty of discussion regarding the belt set up online, but not all of it is really relevant to what we do in road racing. There is a known issue with the main drive belt system, what is commonly known is that when the engine is utilized in a high demand situation, consistently run at higher RPM’s, the main drive belt will come off. The way the belt drive is set up on these cars is unique and a bit infuriating, but not something we can’t deal with. If you take a close look at the image above we can start to understand the problem with this system. As you can see there is one belt that drives from the crankshaft pulley. This main belt only drives the AC compressor, then the AC compressor has an additional pulley behind the main belt on which another belt is driven that runs the alternator and more importantly the water pump. When the main belt leaves, you run a significant risk of overheating due to the loss of drive to the waterpump. This has actually happened to me.

In the video to the right, at the 9:25 mark you can see the belt actually come off the car and in the rear camera flopping around on track, and of course the subsequent overheating.

You will find various opinions for a solution online, including the suggestion to update to a TTRS main crank pulley and tensioner. But, I have found something that works really well for me so that is what I will suggest as a solution here. I am using one of the commonly available under-drive crank pulleys. You can often find these used for a steal online because they have fallen out of fashion with the street tuner crowd. When added into the system on their own, they really do not help the belt problem, you need the complete solution. What I have found is that the belt gets harmonics in it at higher RPM, these harmonics cause the belt tensioner to bounce up and down so the belt tension is not consistent which accelerates wear on the belt and eventually causes the belt to shred itself and come off of the pulleys, this has happened to me twice, the first time the engine overheated on track, after that I set up my RaceCapture Pro3 data system to alert me when the coolant temperature started to rise and/or the battery voltage started to drop, that strategy helped save the 2nd engine. But, ultimately what we want to save is track time, no one wants to end a session early or get a DNF because of a drive belt coming off. My solution, remove the offending part, which is the tensioner. I remembered this strategy from the TDI cup days, on the TDI cup cars the accessories were removed and the alternator was run from a belt which only ran on the crankshaft and alternator, no tensioner. So what I did was to remove the tensioner and find a belt which runs tight on just the crankshaft and the AC compressor. This has solved the problem for me. In order to install this belt you need to remove the 2nd belt from the alternator and water pump on top to take the tension off of it, then you remove the 3 bolts which retain the AC compressor to the sub-frame bracket on the engine. Leave the 2nd belt in place on the AC compressor pulley and install the shorter belt around the crankshaft pulley and AC compressor, then re-install the bolts for the AC compressor. The act of bolting the AC compressor to back onto the engine is what tensions the belt. Then reinstall the belt around your accessories, and you are ready to go. This has completely cured the problem of losing the belt on the 07K for me and is a perfect solution for road racing applications. You are able to continue to use the under-drive pulley which I have found in back to back dyno testing to be worth about 4hp across the entire rev-range, and you will no longer see the belts flopping down the track in your rear video.

This solution is great for those racing on a budget or in a class that does not allow substitution of the stock water pump, etc. If you are in a more open class, or you have a much larger budget, you might consider an electric waterpump and a custom alternator bracket and alternator moved down low to run off of the crankshaft. In Improved Touring we can’t install an electric waterpump, so I am using this method to cure this issue. I would like to find a partner who can reliably supply some AC delete pulleys, that would be the next step in development for me on this aspect of the engine. Keep an eye on my blog here at raceconover.com I’ll be adding some additional insights on the platform in upcoming posts.